Hatip Mah. Ali Osman Çelebi Bulvarı Günaylar Ticaret Merkezi No:108/CC Çorlu / Tekirdağ, 59860 TURKIYE

Hakkımızda

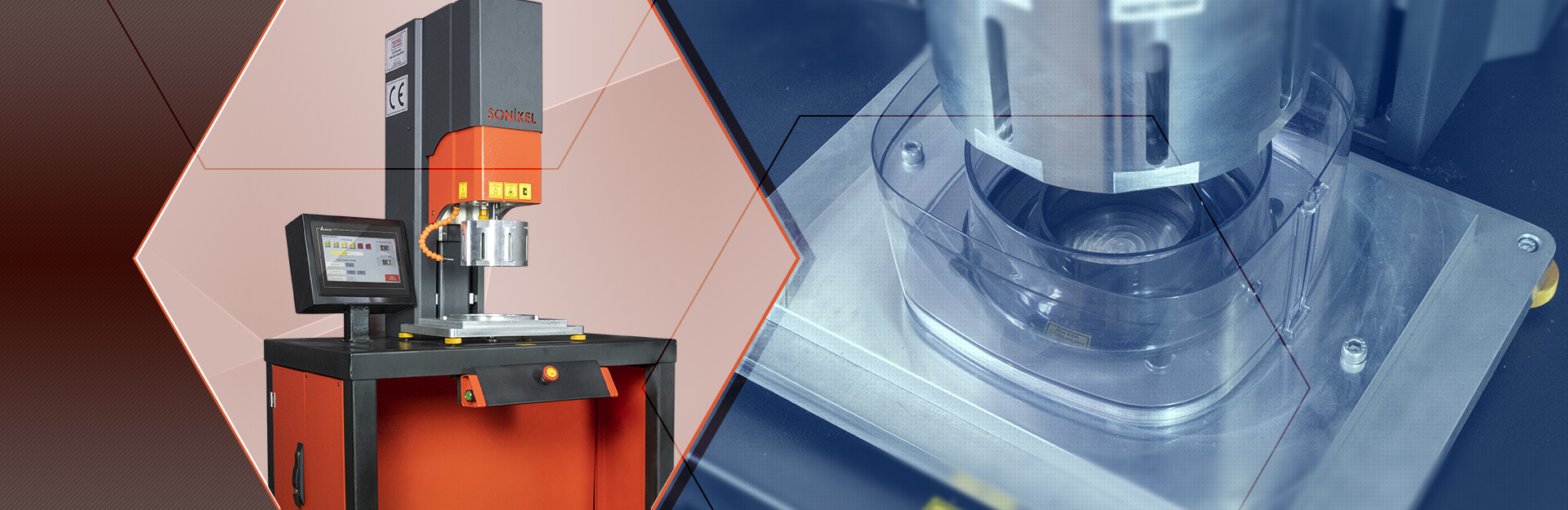

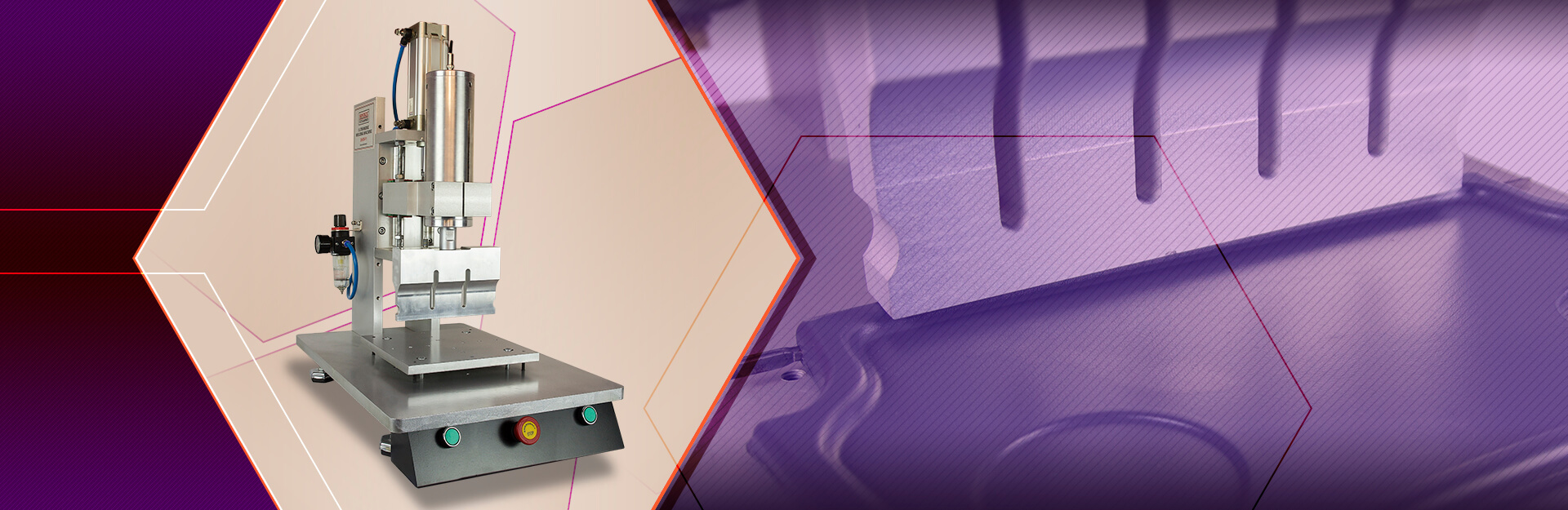

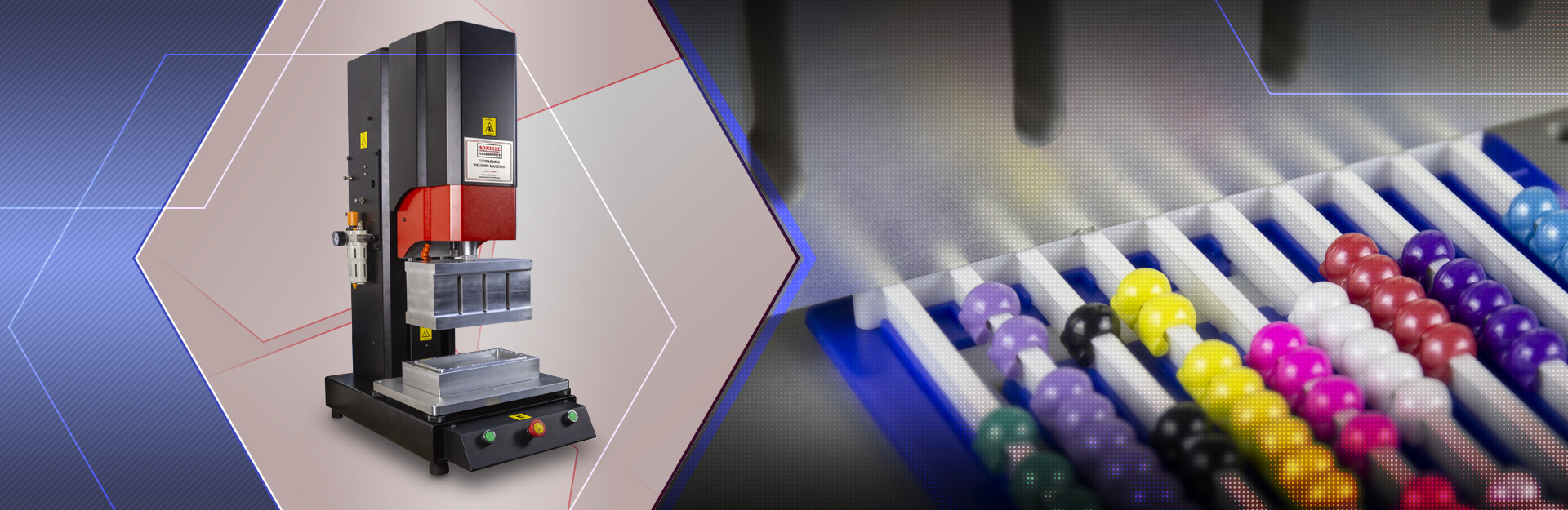

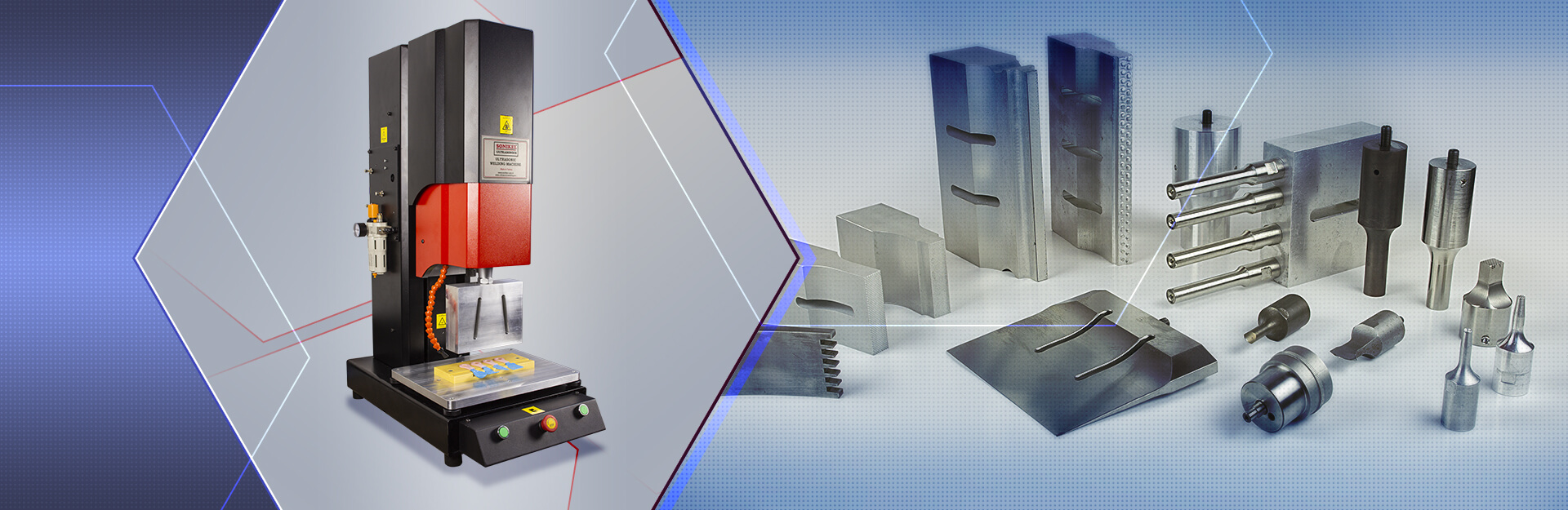

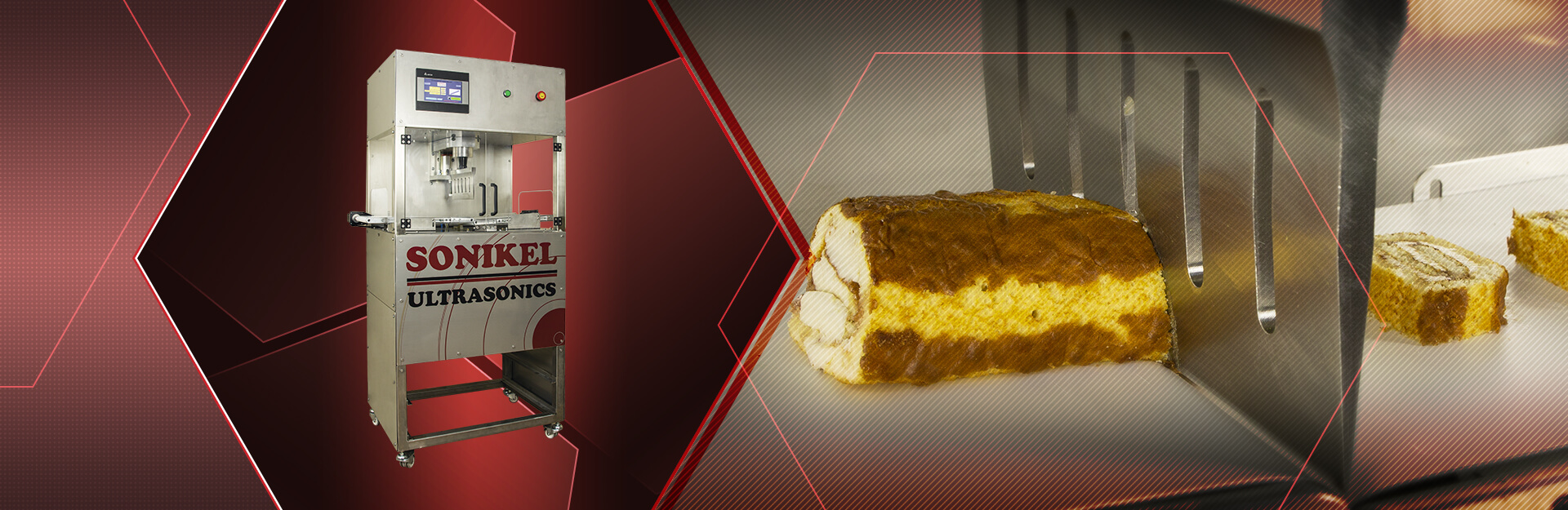

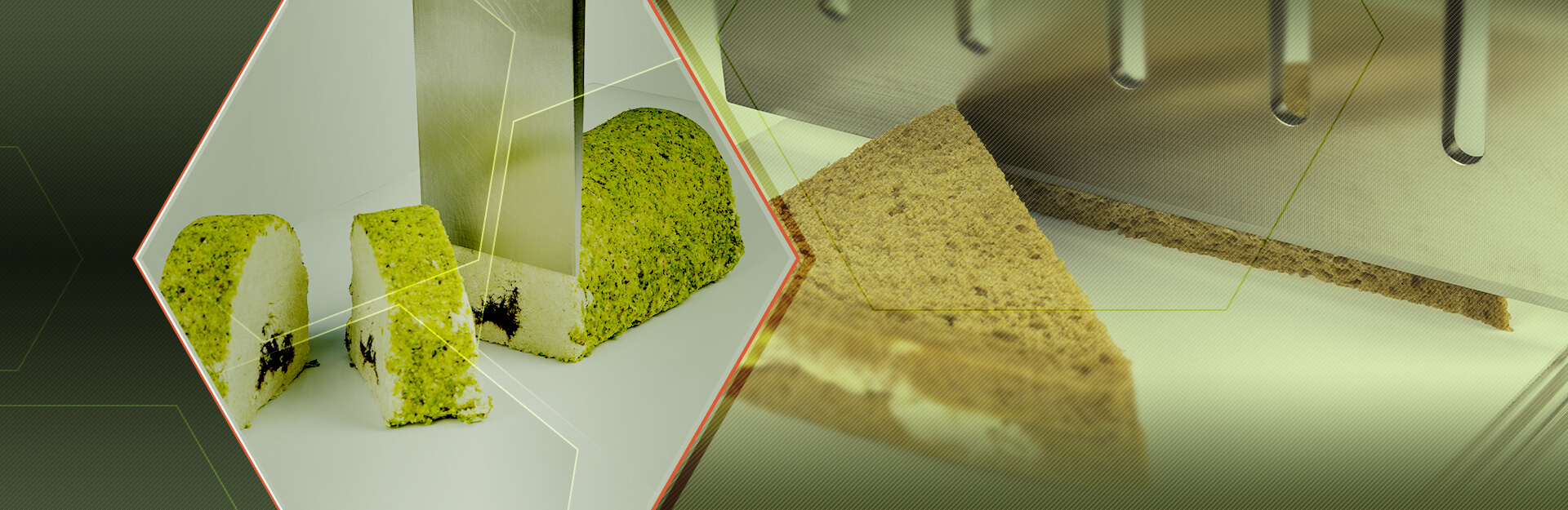

Yenilikçi Ultrasonik Çözümler

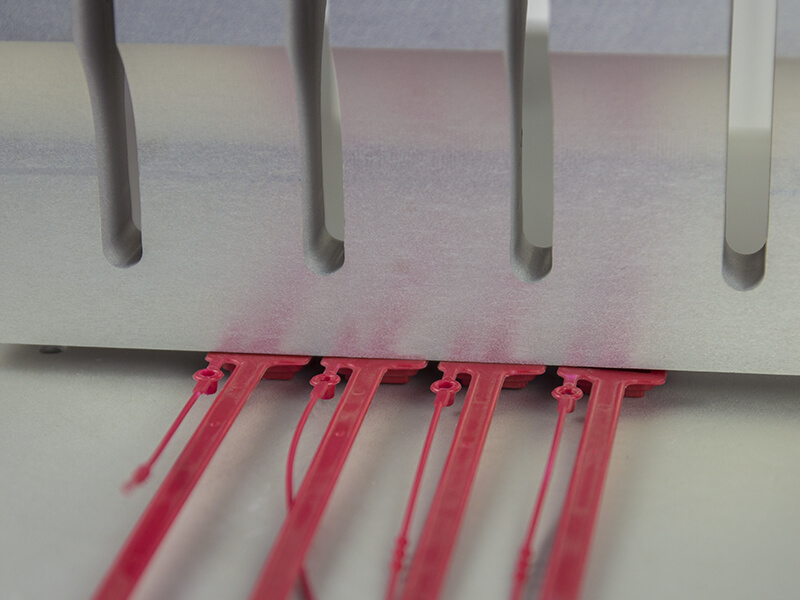

Sonikel Ultrasonik, siz değerli müşterilerimizin ihtiyaçları doğrultusunda ultrasonik teknolojiyi kullanarak plastik kaynak ve ultrasonik kesim işlemlerini gerçekleştiren makine ve otomasyon çözümleri sunmaktadır.

Teknik servis ve yedek parça bölümleriyle de müşterilerinin satış sonrası memnuniyetini sağlamayı kendisine ilke edinmiştir. Hizmet anlayışı, satışta olduğu kadar satıştan sonra da müşterinin yanında olma prensibi üzerine kuruludur.

Yenilikçi yapısı ve Ar-Ge gücüyle, endüstrinin farklı problemlerine ekonomik ve etkin çözümler geliştirmektedir.

Kaliteli Malzeme

Sağlam ve Dayanıklı Ürünler

Müşteri Memnuniyeti

Fuarlar

Katılımcısı olduğumuz fuarlarımızı bu alandan inceleyebilirsiniz.